Injection Molding

Success in injection molding can only be assured when a robust manufacturing process is established and unexpected variations to the process are not permitted to occur. At Moraine Plastics, our facility is “purpose-built” to provide a stable environment for the manufacture of plastic parts. All aspects of product realization are closely monitored and controlled to ensure process consistency. Your products will embody the highest standards of quality from cycle to cycle, shift to shift, and year after year.

The Plant

We welcome your visit to Moraine Plastics and look forward to showing you the centerpiece of our enterprise… our 20,000 ft² molding room. Within this highly-configurable work space, we are able to serve the unique needs of each customer including manual operations, multi-operator work cells or completely automated configurations. Setup and tear-down is accomplished quickly with the assistance of overhead cranes in each molding bay. Many machines are equipped with robots for automated part removal.

Process Control

The molding room is self-contained and air-conditioned for the comfort of our workers and to maintain a highly stable processing environment. A closed-loop chilled water system provides cooling water to the molds and is maintained year-round at ±2°F. Once established, the setup parameters for each job are saved electronically within the machine controls, and are then recalled for subsequent production requirements.

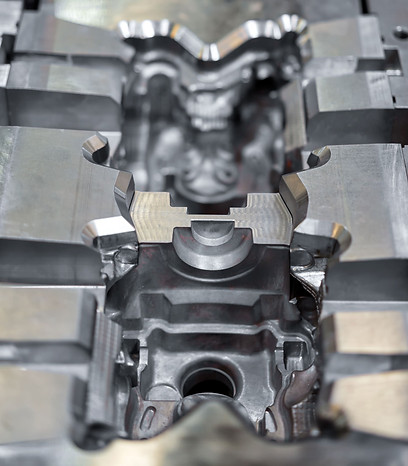

Equipment

The primary processing equipment at Moraine Plastics ranges in size from 50 tons to 650 tons and includes both hydraulic and all-electric molding machines. We have established a comprehensive preventative maintenance program to ensure that all processing equipment is maintained in a constant and predictable state of readiness to serve customer requirements