The 5 Types of SPI Mold Classifications and Why They Matter

- MP Webmaster

- Jul 3

- 4 min read

Updated: Jul 8

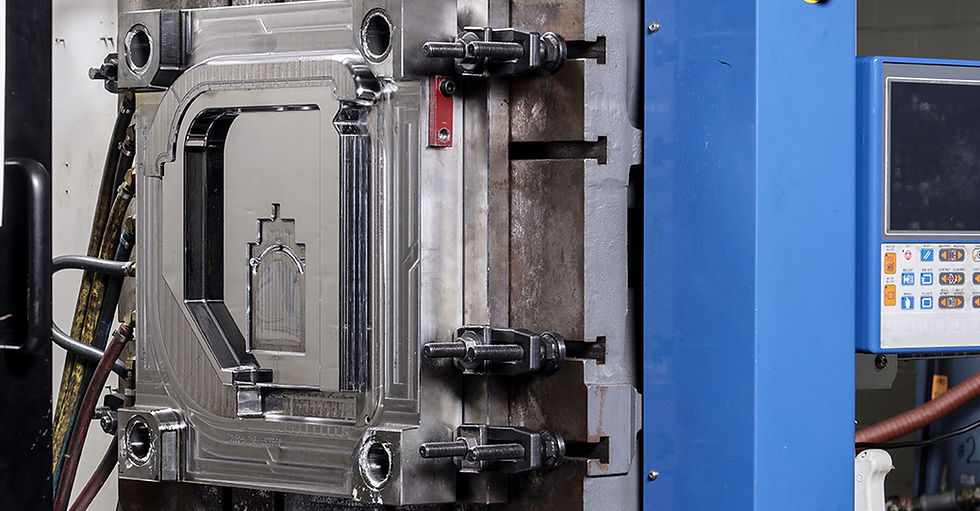

When it comes to injection molding, the mold is everything. It’s the foundation of your part’s quality, your production efficiency—and your bottom line. But not all molds are built the same. If you’re new to the world of custom plastic parts, or even if you’ve been in it a while, understanding SPI mold classifications is one of the smartest things you can do.

These five classifications—developed by the Society of the Plastics Industry (SPI)—help manufacturers, engineers, and buyers get on the same page about how durable, how precise, and frankly, how expensive a mold will be.

At Moraine Plastics, we use the SPI system as a starting point when we consult with customers on tooling. It helps clarify expectations early—and saves you from expensive mistakes later.

What Is an SPI Mold Classification?

In short, SPI mold classifications are a standardized way of rating injection molds based on:

Expected mold life (number of cycles)

Type of steel or aluminum used

Level of construction precision

Intended use case (prototype vs. production)

They range from Class 105 (temporary prototype molds) to Class 101 (built like a tank and ready for 24/7 production). Each class serves a specific need—and choosing the wrong one could cost you.

The 5 SPI Mold Classes (And What They're Good For)

🟢 Class 101 Mold – Built to Run Millions

Mold life: 1,000,000+ cycles

This is the top of the line. If you're planning to produce high volumes over multiple years—think consumer products, automotive components, medical devices—you want a Class 101 mold. These are built from hardened tool steel and designed to last through aggressive, around-the-clock use.

“We’ll always recommend Class 101 for long-life parts,” says Gerry Ford, Owner of Moraine Plastics. “Yes, it costs more up front—but it pays for itself in reliability and cost per part over time.”

Good for:

Multi-year production

Mission-critical parts

Low cycle times, tight tolerances

Key features:

Hardened steel cavity and core (minimum 48 Rc)

Corrosion-resistant materials

High-end cooling systems and runners

🟡 Class 102 Mold – High Production, Less Intensity

Mold life: Up to 1,000,000 cycles

Not every job calls for the armored tank that is Class 101. Class 102 is the working-class mold of the industry: tough, dependable, and more affordable. Still made with high-quality steels, but without some of the overbuilt extras.

If you're producing hundreds of thousands of parts—but not millions—Class 102 is a smart, efficient choice.

Good for:

Mid-to-high volume parts

Seasonal or limited run consumer goods

Parts with moderate wear

⚪ Class 103 Mold – The Industry Workhorse

Mold life: Up to 500,000 cycles

This is your go-to mold for general production. It’s what many manufacturers use for short- to medium-life parts. Mold steel is typically pre-hardened and less expensive to machine, which keeps costs down. But it’s still durable enough to hold tolerances and maintain part quality.

At Moraine Plastics, we often recommend Class 103 for companies that are launching new products with uncertain volumes.

Our take: Don’t overbuild. If your forecast is 50,000–100,000 units, Class 103 gets the job done without overinvesting.

Good for:

Mid-volume production

Early-stage product launches

Flexible, low-risk tooling

🔵 Class 104 Mold – Short Runs & Bridge Tooling

Mold life: Under 100,000 cycles

This is where tooling becomes tactical. Class 104 molds are often used as bridge tools—interim molds used to get to market while a longer-life Class 102 or 101 tool is in development. They’re built faster, with softer steels or aluminum, and lower cost.

But be warned: you get what you pay for. These molds wear faster, cycle slower, and require more frequent maintenance.

Good for:

Low-volume production

Bridge tooling

Budget-conscious startup runs

Key tradeoff: Fast, cheap, and flexible—but don’t expect it to last.

🔴 Class 105 Mold – Prototypes Only

Mold life: Under 500 cycles

If Class 101 is a tank, Class 105 is a test balloon. These molds are temporary tools, often made from aluminum or even soft epoxy, meant for a handful of test parts—not production.

They’re great for validating part geometry, checking fit and function, or demoing early-stage concepts.

But don’t try to squeeze production from a prototype mold. It’ll fail. Fast.

Good for:

Design verification

Functional testing

Pre-launch presentations

Summary Chart: SPI Mold Classifications

Class | Mold Life | Material | Best Use |

101 | 1,000,000+ | Hardened Steel | Long-life, high-volume production |

102 | Up to 1,000,000 | Tool Steel | Mid-to-high volume parts |

103 | Up to 500,000 | Pre-Hardened Steel | General production |

104 | Under 100,000 | Aluminum or Soft Steel | Short runs, bridge tooling |

105 | Under 500 | Aluminum / Soft Tooling | Prototypes only |

Choosing the Right Mold: It’s About the End Game

Too often, we see companies under- or over-invest in tooling because no one walked them through their options. Here’s our blunt advice:

Don’t use a prototype mold for production. It won’t hold up.

Don’t spend $40,000 on a Class 101 mold if you only need 20,000 parts.

Do think long-term. Upfront savings mean nothing if your mold fails mid-run.

And don’t make the decision in a vacuum. At Moraine Plastics, we help customers select the right tooling class based on their product lifecycle, target volume, material selection, and long-term growth plans.

* Learn more about our tooling and engineering capabilities

Want More Technical Detail?

If you're diving deeper into tooling specs or just want to explore the original SPI classifications, the Plastics Industry Association is the source:

Final Word from Moraine Plastics

Choosing the right mold class isn’t just about today’s order—it’s about your entire production strategy. Whether you’re prototyping a medical device or scaling up for a national product launch, we’ll help you choose smart, build smarter, and avoid surprises down the line.

“We’re not in the business of selling molds,” says Gerry Ford. “We’re in the business of helping customers scale. And that means building the right tool for the job—not just the biggest one.”

Ready to Talk Tooling?

Contact Moraine Plastics for a no-pressure consultation. Whether you need a short-run bridge mold or a million-shot production tool, we’ll walk you through your options—no guesswork required.