Choosing the Right Injection Molding Machine for Your Project

- MP Webmaster

- Sep 15

- 4 min read

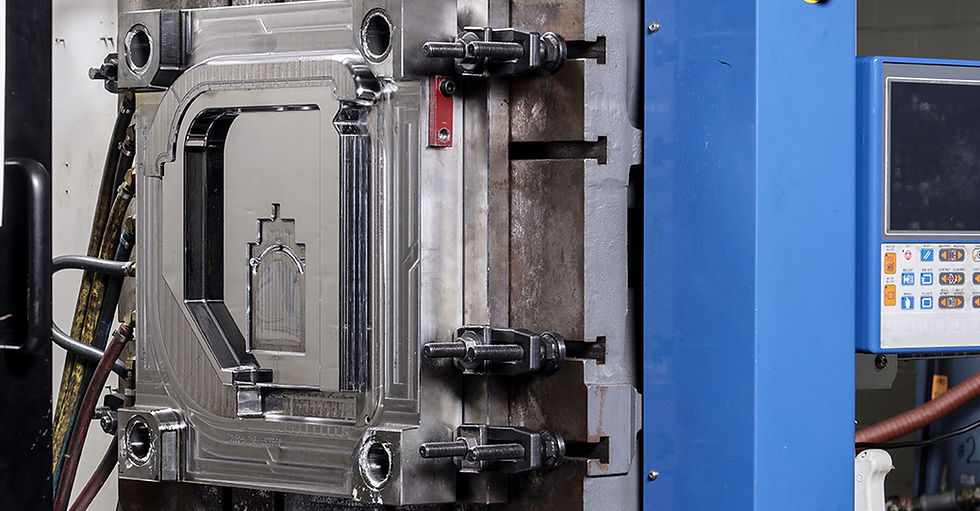

When it comes to injection molding, there’s no such thing as a one-size-fits-all machine. Walk through the floor at Moraine Plastics and you’ll see why. One press might be cranking out sturdy truck components, while a smaller machine nearby handles lightweight consumer parts with surgical precision. Both are doing their jobs perfectly — but only because they were carefully matched to the projects they serve.

Key Takeaways

Start with the part: materials, complexity, and industry requirements shape the machine choice.

Match the machine type (hydraulic, electric, hybrid) to your production goals.

Factor in volume and cycle time — they often drive profitability more than specs.

Size tonnage carefully: enough to hold tight, but not so much that it damages molds or wastes energy.

Look for features that boost quality and efficiency, not just the latest gadgets.

Think long-term: support, training, and maintenance can outweigh the initial price tag.

Why Project Fit Comes First

The first step in choosing a molding machine isn’t flipping through brochures. It’s taking a hard look at what you’re making and where it’s going.

One customer came to us with a design for a compact automotive clip. They were leaning toward a big hydraulic press because “bigger felt safer.” But when we walked them through the part’s size, complexity, and required tolerances, it became clear that an all-electric machine would save them money, cut cycle times, and give them more precise results. That’s the kind of decision that pays off not just once, but over years of production.

As Gerry Ford, president of Moraine Plastics, likes to say: “The machine isn’t the star — the part is. Our job is to make sure the equipment is tuned to bring that part to life consistently, efficiently, and at the right cost.”

Knowing Your Machine Types

Every press has its personality:

Hydraulic machines are the heavy lifters. They thrive on large parts that need tons of clamping force.

Electric machines are the precision players. They shine when tolerances are tight, cycles are fast, and energy efficiency matters.

Hybrids give you a bit of both, offering flexibility for manufacturers who need muscle and finesse in one package.

We’ve had projects where the hybrid option saved the day — a midsize industrial component that demanded the brawn of hydraulics, but with the repeatability of an electric. Without that blend, quality would’ve suffered, and so would margins.

Production Volume: The Silent Factor

It’s easy to focus on specs, but production volume and cycle time are often the silent deal-breakers.

We worked with a customer producing thousands of parts daily. They needed a machine that could shave seconds off the cycle. Over the course of a month, that small efficiency translated into thousands of extra units and a noticeable boost to their bottom line. On the flip side, another client producing low-volume specialty components would have wasted capital investing in a machine designed for speed instead of flexibility.

The Tonnage Equation

Tonnage isn’t glamorous, but it’s essential. Too little clamping force, and you’ll see flash creeping out of the mold. Too much, and you risk wearing down both machine and mold prematurely. It’s about balance.

Ford puts it plainly: “You wouldn’t bring a bulldozer to plant a rose garden. Power has to be right-sized for the job, or you pay for it later.”

Features That Matter in the Real World

Temperature control systems, automation, high-speed injection — these features aren’t bells and whistles. They’re tools that can make or break part quality and labor efficiency. One of our clients integrated robotic part removal on a mid-range press and cut operator labor costs in half. That’s the kind of feature that justifies itself fast.

Beyond the Purchase Price

A molding machine isn’t a one-time expense. Energy draw, maintenance, spare parts, and operator training all factor into its true cost. We often remind clients that the cheapest machine upfront can easily become the most expensive long-term if it guzzles power or sits idle waiting for repairs.

That’s where supplier support matters. “The right partner isn’t just selling a press,” Ford explains. “They’re standing beside you when it’s 2 a.m. and a part won’t run.”

At the end of the day, the “best” injection molding machine is the one that fits your project like a glove. Choosing wisely means fewer headaches, lower costs, and parts that meet the standards your customers demand. At Moraine Plastics, we’ve built our reputation on helping manufacturers make those calls with confidence. Because when the machine and the project are in sync, everything else falls into place.

FAQs (Frequently Asked Questions)

What factors should be considered when choosing an injection molding machine for a project?

When choosing an injection molding machine for a project, factors such as the type of material to be used, the size and complexity of the part, production volume, and budget should be considered.

What are the different types of injection molding machines available?

There are several types of injection molding machines available, including hydraulic, electric, and hybrid machines. Each type has its own advantages and is suitable for different types of projects.

What are the advantages of hydraulic injection molding machines?

Hydraulic injection molding machines are known for their high clamping force, ability to handle a wide range of materials, and cost-effectiveness for larger production runs.

What are the advantages of electric injection molding machines?

Electric injection molding machines are known for their precision, energy efficiency, and cleanliness. They are suitable for high-precision molding and cleanroom environments.

What are the advantages of hybrid injection molding machines?

Hybrid injection molding machines combine the advantages of both hydraulic and electric machines, offering high precision, energy efficiency, and flexibility in material handling.

How can I determine which injection molding machine is best for my project?

To determine the best injection molding machine for your project, it is important to consider the specific requirements of the project, such as material type, part size and complexity, production volume, and budget. Consulting with a knowledgeable supplier or manufacturer like Moraine Plastics can also help in making an informed decision.