6 Things To Look For In A OEM Manufacturing Partner

- MP Webmaster

- May 30

- 4 min read

Real talk from a team that’s been doing this for over 50 years.

If you’re reading this, odds are you’re in the thick of sourcing a OEM manufacturing partner. Maybe you’ve got a new part on the drawing board. Maybe your current supplier’s ghosted you (again). Or maybe you’re just tired of playing whack-a-mole with quality issues.

Whatever brought you here, we’ll keep this simple: the right manufacturing partner makes your life easier. The wrong one? They’ll cost you time, money, sleep—and sometimes, customers.

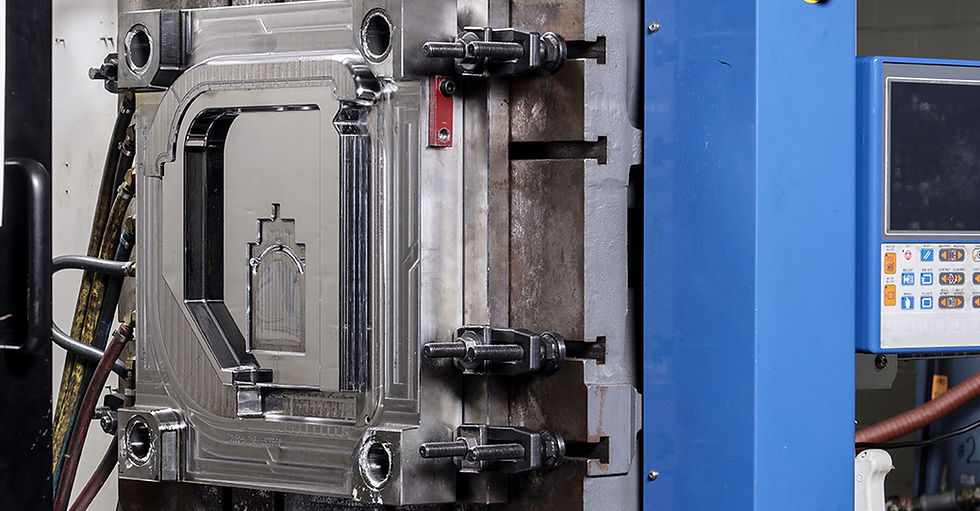

So how do you separate the good from the risky? After five decades in the injection molding business, we at Moraine Plastics have a few thoughts. Here’s what we’ve learned to look for in a long-term manufacturing relationship—and what we’ve built our company around.

You May Also Like:

1. First, make sure they actually know what they’re doing.

There’s a big difference between a manufacturer that says “Sure, we can mold that” and one that’s already molded something like it a hundred thousand times.

You want someone who understands your part, your material, and your industry. Someone who can tell you why your design might warp under stress—or how to tweak it so you don’t run into tooling problems later. That only comes from experience.

We’ve molded parts for Ford, John Deere, and Target. We’ve done overmolding, tight-tolerance geometries, and parts that need to hold up to oil, heat, vibration—you name it. Our engineers don’t just get your drawings—they get what’s behind them.

2. Quality isn’t a buzzword. It’s the whole ballgame.

It’s easy to throw around phrases like “top-tier quality” or “ISO certified.” But when your parts show up out of spec, those phrases don’t matter much.

At Moraine, we don’t do wishful thinking. We have systems in place to catch problems before they reach your dock. Our team uses real inspection equipment, documents everything, and doesn’t flinch when something needs to be corrected. Because mistakes happen. It’s how you respond that counts.

As Jerry Ford, our owner, puts it:

“Quality isn’t about having a perfect production run. It’s about having the discipline to fix it fast when something’s off—and the guts to tell the customer the truth.”

That’s how we operate. And we think you deserve that kind of honesty.

3. If they don’t have a track record, you’re their learning curve.

A first-time molder might be cheaper on paper—but what’s the cost of a delayed launch? A rejected batch? A customer walking away?

We’ve been at this since the early 1950s. We’ve seen tooling transfers mid-program. We’ve solved headaches left behind by other suppliers. We’ve ramped up fast for customers who suddenly needed twice the volume they thought they would. This isn’t our first rodeo, and frankly, we like the weird problems. That’s where we shine.

4. You need real communication—not just status updates.

You know what’s worse than bad news? No news. Or cryptic updates that sound like a press release.

We keep it real. You’ll know who’s managing your program. You’ll hear from us when things are good, and when something’s not. We talk through your launch timelines. We flag issues early. And we make sure you’re never left guessing what’s going on behind the scenes.

When you’ve got a million-dollar order riding on a plastic part, you want a partner who picks up the phone. That’s us.

5. Cost is more than just price-per-part.

Yes, cost matters. But chasing the lowest price without thinking about geography, lead times, or shipping costs? That’s how you end up saving pennies but losing sleep.

We’re based in the Midwest—smack in the middle of the country, with rail access and affordable freight options. We don’t have West Coast rent or overseas timezone headaches. What we do have is reliable delivery and competitive pricing that actually makes sense when you look at the full picture.

6. Flexibility isn’t a nice-to-have. It’s the only way to survive.

Your business is going to change. Demand will spike. Your customers will move deadlines. You’ll need to revise a part that just got kicked back from testing.

The question is: will your molder bend—or break?

At Moraine, we build our own molds in-house and maintain them ourselves. That gives us the freedom to pivot fast, fix tooling issues on the fly, and make changes without going through three layers of overseas subcontractors.

We’re not just here to fill POs. We’re here to build something that lasts—with you.

Choose a Partner, Not a Problem

At the end of the day, parts are parts. But the people who make them? That’s where the difference lies.

We’re not trying to be the biggest shop. Just the most dependable one. The one that calls you back. The one that sweats the details. The one that treats your business like our own.

If you’re ready for a manufacturing partner who’s in it with you, not just in it for the job—give us a call. We’d love to earn your trust.

“You don’t stay in this business 50 years by doing it halfway. You stay by showing up, doing what you say, and fixing what needs fixing.”— Jerry Ford, Owner, Moraine Plastics

FAQs (Frequently Asked Questions)

What industries does Moraine Plastics serve?

We primarily serve the automotive, electronics, and general OEM markets—but if your product needs reliable, high-volume injection molding, we’re happy to talk.

Do you make your own molds?

Yes. We design, build, maintain, and repair molds in-house. That gives us full control over quality and turnaround time.

Can you handle large-volume orders?

Absolutely. High-volume production is our specialty. Whether you're ramping up for launch or scaling an existing part, we have the equipment and process to keep up.

Where are you located?

We're based in the Midwest, specifically in West Bend, Wisconsin, which gives us a great logistics advantage—central to major distribution routes and cost-effective to ship nationwide.

How do you approach new projects?

We start with a deep dive into your part, your goals, and your timeline. From there, we’ll walk you through tooling, material selection, quality checkpoints, and production ramp-up.

How can I get started with Moraine Plastics?

Simple. Reach out to our team—we’ll schedule a discovery call, review your specs, and map out a path forward that fits your needs.