What is Injection Molding Tooling?

- MP Webmaster

- May 29

- 6 min read

It’s the Backbone of Modern Manufacturing

At Moraine Plastics, we live and breathe plastic injection molding. But what many people don’t see behind the curtain is the beating heart of it all: the tooling.

Injection mold tooling isn’t just about the mold—it’s the foundation that makes scalable, high-precision plastic manufacturing possible. Whether you're holding a car dashboard panel, a laptop hinge, or a tiny gear inside your coffee machine, there's a good chance it came from a mold carefully engineered and maintained by experts like those on our team.

So what exactly is injection molding tooling, and why does it matter so much in industries like automotive, electronics, and OEM manufacturing? Let’s take a deeper dive.

The Tool Behind the Mold

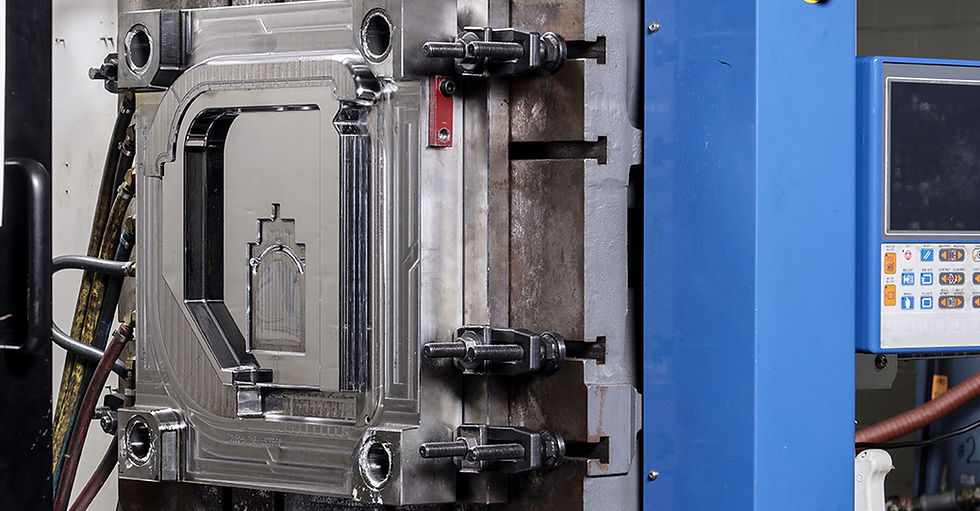

Injection molding tooling refers to the custom-made steel or aluminum mold that shapes molten plastic into a final product. It’s the precision-crafted hardware where high-pressure, high-heat resin flows, fills, cools, and becomes a part.

Creating these tools is no small feat. They’re not off-the-shelf items; they’re tailor-made for each project, often costing tens of thousands of dollars. But the payoff? They enable high-speed production of hundreds of thousands—or millions—of identical parts with tolerances down to fractions of a millimeter.

For manufacturers who value consistency and efficiency, that level of control is priceless.

Inside the Mold: What Tooling Actually Looks Like

If you could open up one of our molds, you'd find two main halves: the core and the cavity. These pieces fit together with surgical precision. When closed, they create a hollow space in the shape of your part. The cavity shapes the outside of the component, and the core shapes the inside.

But that’s just the beginning. A full injection mold tool also includes:

Cooling channels to regulate temperature and reduce cycle times

Ejector pins that pop the part out once it’s cooled

Guide pins to ensure perfect alignment

Runners and gates that direct the plastic to where it needs to go

Each of these parts must be engineered with an obsessive level of detail. One misalignment, one degree of temperature difference, and you’re looking at defective parts or production delays.

The Mold-Making Process: More than Just Metal

Designing and building injection mold tooling is a multi-stage process that blends creativity, engineering, and precision manufacturing. It typically includes:

Stage | What Happens |

Design Discovery | Requirements gathering, part specs, material selection |

3D CAD Modeling | Creating digital models of the tool, core, and cavity |

Simulation & Testing | Software simulates material flow, pressure, and cooling |

Tool Fabrication | CNC machining, EDM, and polishing of mold components |

Tool Trials | Testing the mold in real-world conditions |

Optimization & Final Approval | Tweak. Test again. Approve. Ship. |

This isn’t plug-and-play—it’s an art form rooted in materials science and design strategy.

The Design Process: Where Precision Meets Creativity

Designing a mold starts well before metal ever touches a machine.

We sit down with the client, review the geometry of the part, its function, its required materials, and where it fits in their assembly line. Sometimes that means integrating complex features like undercuts or snap fits directly into the mold so that no secondary machining is needed.

Our engineers use advanced CAD software to model the tool in 3D. Then, we simulate how the molten plastic will flow through the tool—identifying potential weak spots, air traps, or uneven cooling before anything is manufactured. This digital "test drive" saves weeks of time and thousands of dollars in guesswork.

Sometimes, we prototype the part using 3D printing or soft tooling to validate design assumptions. Once everything checks out, the tool is machined—often using CNC and EDM (electrical discharge machining)—from hardened tool steel or aluminum.

Choosing the Right Material for the Mold

Tool steel is the gold standard for production tooling. It’s durable, wear-resistant, and can handle millions of cycles without breaking a sweat. That makes it ideal for long-running jobs like automotive connectors or dashboard panels.

Aluminum, on the other hand, is faster and cheaper to machine. It’s perfect for lower-volume runs or prototyping, where speed and cost matter more than tool longevity.

In recent years, advanced alloys and hybrid molds have started gaining ground, offering lightweight benefits or faster cooling times without sacrificing strength.

Types of Tooling: One Size Definitely Does Not Fit All

Not every tool does the same job. At Moraine Plastics, we build tools suited for the production volume and part complexity.

Prototype molds help us test a part quickly and inexpensively

Production molds are built for endurance—millions of cycles without fail

Multi-cavity molds can create several identical parts in one shot, increasing throughput

Family molds produce different parts in the same cycle—useful when components will be assembled together

Each comes with trade-offs. A multi-cavity mold, for instance, must be perfectly balanced so that all cavities fill evenly. Otherwise, you risk inconsistency or part defects.

Why Precision Matters—A Lot

Here’s something Gerry Fold, the owner of Moraine Plastics, often say: “If the tool is even slightly off, everything downstream suffers.”

In industries like automotive or electronics, where parts need to snap, lock, rotate, or press together precisely, there’s zero room for misalignment. One mold flaw could cause hundreds of parts to be scrapped—and worse, delay the launch of an entire product.

That’s why we use coordinate measuring machines (CMMs) to inspect our tools down to the micron. And why we schedule preventive maintenance before problems happen—not after.

Real-World Challenges We Solve

Here’s a quick story. A client once came to us with a highly complex housing for an EV component. The part needed to lock perfectly with another piece, withstand heat, and be watertight. But it also had multiple undercuts and thin walls.

Instead of saying “not possible,” our tooling engineers developed a collapsible core solution inside the mold—a mechanism that retracts during part ejection. It took weeks of planning and trial runs, but the result was a 100% functional part produced reliably at scale.

These are the kinds of “unsolvable” problems that mold tooling exists to conquer.

Maintenance Isn’t Optional—It’s Smart Business

Think of a mold like a high-performance engine. You wouldn’t run it hard for a million miles without oil changes and tune-ups, right?

Routine cleaning, lubrication, alignment checks, and wear monitoring keep tooling in top condition. At Moraine Plastics, we log every mold’s performance and schedule downtime proactively. That keeps our clients' production lines running smoothly, without surprises.

Looking Ahead: Smarter Tooling on the Horizon

Tooling is getting smarter—literally.

Some of our newest mold systems integrate sensors to track temperature, pressure, and flow in real time. This data helps us make live adjustments during runs or anticipate maintenance needs before they become problems.

We’re also starting to incorporate 3D-printed inserts into molds to experiment with complex cooling geometries that traditional machining can’t match. This opens the door to faster cooling, tighter tolerances, and shorter cycle times.

If you’re curious, check out this YouTube walkthrough from Autodesk showing how simulation software helps optimize injection mold designs before they’re even made.

Final Thoughts: Why Injection Molding Tooling Is More Than Just a Mold

Injection mold tooling is one of those behind-the-scenes processes that quietly makes modern life possible. It’s not flashy. But it’s deeply impactful.

At Moraine Plastics, our tooling isn’t just a line item. It’s an investment in your product’s success—from the first design sketch to the millionth part rolling off the line.

So whether you’re an engineer designing your next product, or a manufacturer scaling up your production, remember: great tooling isn’t optional. It’s everything.

Want to talk to a real human about your next tooling project? Contact us and let’s build something great—together.

FAQs (Frequently Asked Questions)

What’s the difference between a prototype mold and a production mold?

Prototype molds are used to test and validate part designs; they’re often aluminum and lower-cost. Production molds are built from hardened steel for long-term, high-volume use.

How long does it take to build a mold?

It depends on complexity, but typical lead times range from 6–12 weeks for full production molds.

Can tooling be reused for future projects?

Absolutely—if the part design doesn’t change, well-maintained tooling can be reused for years.

Is injection mold tooling expensive?

It’s a significant upfront investment, but it pays off quickly with high-volume production—especially when you consider part consistency, reduced labor, and speed to market.